Die Casting in Malaysia: A Cornerstone of Industrial Precision

Die Casting in Malaysia: A Cornerstone of Industrial Precision

Blog Article

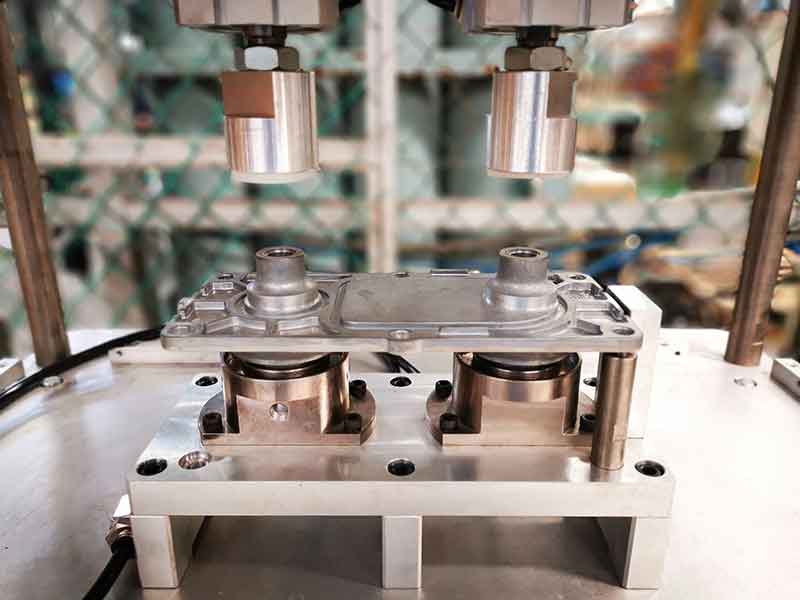

Die casting is a pivotal manufacturing process, supplying high-quality and long-lasting performance for a wide range of industrial applications. In Malaysia, die casting has become a vital manufacturing process, supporting industries like electronics, automotive construction, construction and consumer goods. The process involves forcing hot metal into a cavity using high pressure and producing intricate and high-quality components. Malaysian firms that specialize in die casting are renowned for their innovative techniques, advanced technologies and dedication to quality, which makes the country a global hub for precision engineering. With a focus on the efficiency and sustainability of die casting is a major part of Malaysia keeps evolving and contributes significantly to the nation's industrial growth.

One of the primary reasons for the widespread adoption of the process in Malaysia is its effectiveness in producing complex shapes with minimal waste of material. Die casting allows companies to create intricate designs and lightweight parts without losing durability or the quality. Aluminum, zinc, and magnesium are the metals that are most frequently used in die casting, each offering unique benefits for specific applications. For instance, aluminum is favored for its excellent strength-to-weight ratio. This makes it a great choice for automotive as well as aerospace components. The ability to customize the process and materials to suit the needs of industry has helped position Malaysia as an industry leader on the international market for die casting.

Innovation is an essential factor in the development of die casting industries in Malaysia manufacturing companies constantly using new technology to enhance the efficiency of their processes. Automation and robotics are essential for modern-day die casting, enhancing production while maintaining accuracy. Advanced simulation tools allow engineers to design molds that are optimized to reduce waste material and improving product quality. A lot of Malaysian businesses have also taken on Industry 4.0 practices, incorporating the use of data analytics as well as IoT-connected devices to their business. These advancements not only increase efficiency, but also help position Malaysia as a leading player on the global production landscape and attracting customers from all over the globe.

Technological innovation is at the heart of Malaysia's industry of die casting which allows companies to improve efficiency, cut costs as well as meet ever-higher quality standards. Utilizing advanced methods including vacuum casting, multi-slide dash casting, and semi-solid metal casting has boosted the capabilities of this industry. Automation and robotics are also making an impact on manufacturing processes, providing the same quality of products and quicker manufacturing times. Digital tools, including simulation software and real-time monitoring devices, enable manufacturers to improve designs and reduce the risk of defects. These innovations reflect the company's determination to remain ahead of the curve in a time of rapid technological advancement. To get more details kindly head to Senadiecasting

The expansion of Malaysia's casting industry is aided by initiatives of the government aimed at fostering innovation and investment. Policies promoting research and development, and incentives to encourage technological advancement, have boosted this sector. Collaborations among industry actors and academic institutions ensure the availability of qualified experts with the most recent technology. Additionally, Malaysia's strategic location and its trade agreement has created a hub of export-oriented manufacturing. The supportive environment has allowed die casting firms to expand their operations and increase their capabilities, ensuring their contribution to the nation's manufacturing growth will be substantial.

Die casting within Malaysia is a prime example of the country's strengths in the field of precision engineering as well as industrial technological innovation. With its ability to produce complex components, use the latest technologies, and focus on sustainable practices, it has a crucial role to play in supporting the key industries and stimulating economic growth. With the demand worldwide for top-quality manufacturing products continues to grow, Malaysia's die casting industry can meet these demands. Through its focus on excellence flexibility, adaptability as well as environmental responsibility This industry not just keeps its place in the global marketplace, and also strengthens Malaysia's standing as an innovator in modern manufacturing.